Just a quick update, I've been tinkering still with the cooling system, trying to dial in when it switches the pump and fan on and off. This configuration I've settled into, I'm quite happy with.

I realized I never posted a link to the sensors themselves, here you go. Just change the color/style to pick what temp range your after.

https://www.amazon.com/gp/product/B07NC98GHM/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1So the sweet spot for my configuration, with the sensor in the head over the exhaust port, and the other sensor just above the radiator outlet, is:

Head - 140° on, 125° off

Radiator - 170° on, 155° off

Since I replaced the sensors, of course it's time to go test it, ASAP. So Sunday I took it back to the lake, and rode up the mountains towards CK again.

At first I was leery of just letting it go, not hitting the pump switch and just trusting the old girl to handle things. So from start to about 2-3 miles in, I had the pump on override. After that, I reached up and flipped it off, and the LED went blue! Woo!

Of course after that I'm watching my temp sensor like a hawk, making sure the pump actually was running. But sure enough, it took care of it.

Once I got to the really steep, rough part of my climb, I was delighted to see the fan also cycled on, right at the 168°-170° mark according to my gauge. Not only that, but it cooled it down while still under full load while climbing, and cycled itself off. So if anybody is looking for a radiator recommendation, I give this one 4 thumbs up.

Before, when I was riding around with the pump on all the time, the temp would always stay somewhere between 140°-155°. It seems to like to be cool, so that's why I went with the lower temp head sensor. From there, it was just a matter of matching up the lower value (off temp) of the radiator sensor with the optimal temp (or slightly above) and bingo, it's automagic!!

Once I get through the really steep section, I pull over to use the facilities. I leave the key on to preserve my trip data, and while I'm taking care of my business, the Honda was taking care of hers! I hear the fan cycle itself on, run for a bit, and then cycle off. The pump never stopped running with the key on. Wow!!!

So I keep going, up through the nasty wash part, till I have to flip to reserve. From there I only go another mile or 2 before turning back. The reason for this was I wanted to use up the gas in it, I had also just received a jug of Motul 800 offroad and wanted to see how it did. When I departed, both tanks were full of the old stuff, and I wanted to time it so I was just about empty before going with the new raspberry juice.

I make it back no problems, run it to just about empty on the reserve, and then fill up with the Motul (40:1). Woo-pow! That's a spicy! The old girl sure seems to like the stuff. So I start heading back up towards CK again, just to see if I make it further with the new blend. At this point, I'm still monitoring things, but I've given up on the pump override switch, I'm satisfied it's coming on as it should.

I get to another climb, not the big one but still enough to make the girl grunt a bit, and I notice the fan light flips to blue. I decide to stop for a bathroom break, and also to verify the fan is still spinning as it should.

No fan.

?

So I hit the override switch. Still no fan.

I'm about 10-12 miles from the staging area, it's all down hill from here. So I decide to abort and head back. I don't want to push it and boil over or something like that.

While driving back, I'm still mulling on this issue. I decide it's got to be either the speed control (unlikely) or the 5th relay I had to add on the negative side of the fan output. The reason I needed this 5th relay is because the speed control does not have a common ground, it's isolated. So I used the NC position of the 5th relay to run the negative from the speed control to the fan (override off) and the NO position to run the negative to the common ground (override on).

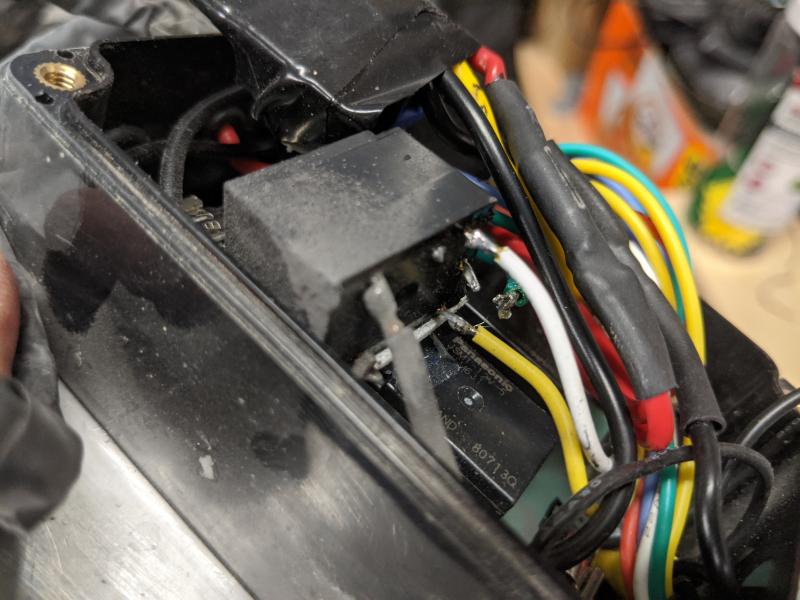

Last night, I pull off my little black box and take a look. Instantly I see the issue. Some dingleberry enginerd forgot to put a strain relief on the wires coming OUT of the box to the fan/pump (both sets share the same grommet), so things vibrated and rattled loose the negative lead (fan negative going out) off of pin 30 of my 5th relay.

Attachment:

broken_joint.jpg [ 65.14 KiB | Viewed 19031 times ]

broken_joint.jpg [ 65.14 KiB | Viewed 19031 times ]

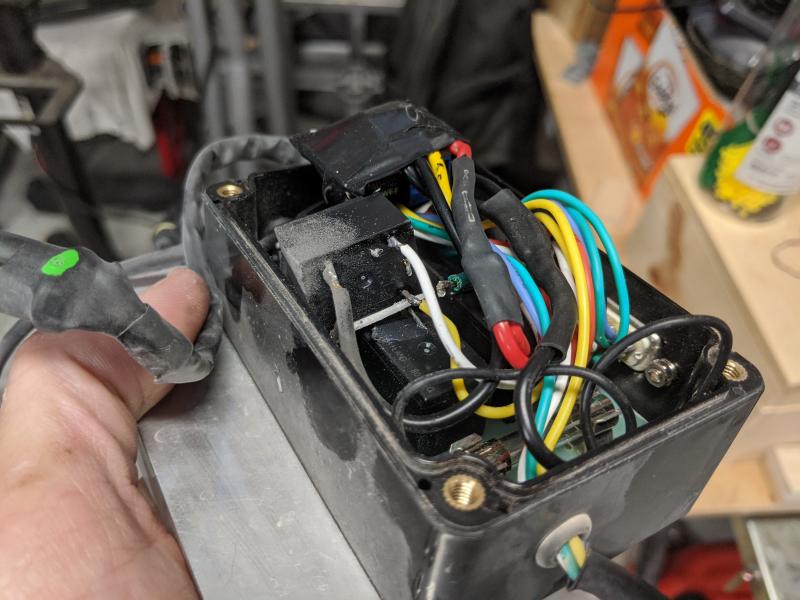

Attachment:

broken_joint_2.jpg [ 65.58 KiB | Viewed 19031 times ]

broken_joint_2.jpg [ 65.58 KiB | Viewed 19031 times ]

With that broke, neither the override nor the automated relay are going to work, yet the lights are still on (fuse is good). I mentioned this to Joe, he suggested rewiring it so I see what the true device state is vs what the state of the relays are (on/off). I shot that down as too much work, however I did like the idea. We chat a bit more, and I think I'm going to figure out some sort of verification light that's visible via the rear view mirror. Just something to see the fan is on, since I can't hear it.

I'm not so worried about the pump, since it's going through one of 2 relays. No extra relay or speed control. Plus I also have the temp sensor, I can see independently if things are going sideways. The fan on the other hand, I don't have any sort of back up verification like that, and I think a nice little LED tucked in somewhere that I can see via rear view will do just fine. Something that powers up with the fan, so if I look up at my HUD and see the LED up there is blue, then I can check my mirror to verify that the fan ACTUALLY is on.

So for now, everything is back online. One other mistake the aformentioned dingleberry made was not putting the connector for the speed control knob outside of the headliner. So I ended up having to cut those wires, and put an additional connector. As penance for my failures, I've taken pictures of the whole process, and I'll start a thread in Tech Stuff. Hopefully you guys will find it useful.

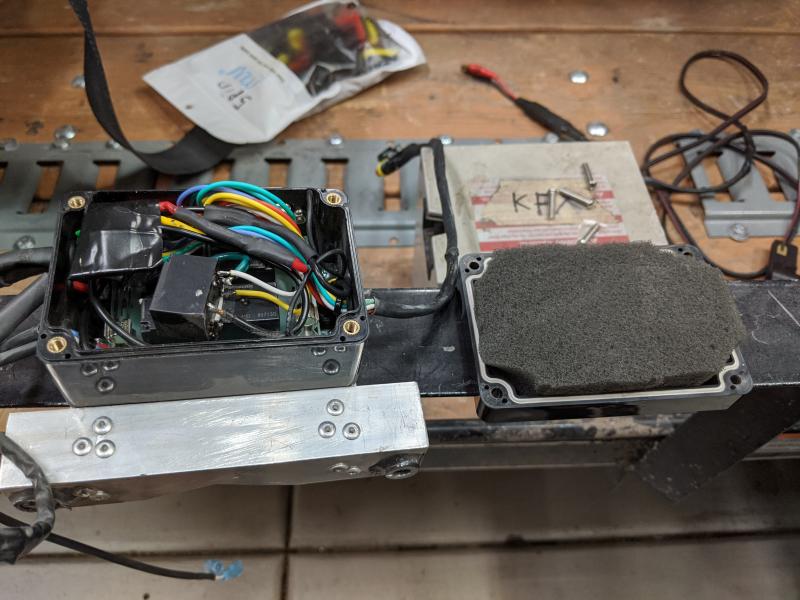

Before I close up my black box and remount it with it's spiffy new connector, I get the strain relief added. I also put in some foam, to keep the 5th relay and the speed control in place. I originally had mounted them to the top of the 4 pack of board mounted relays using some double sided tape, however that just wasn't enough. So squishing some foam between the devices and the lid should take care of it.

Attachment:

all_bettah.jpg [ 68.65 KiB | Viewed 19031 times ]

all_bettah.jpg [ 68.65 KiB | Viewed 19031 times ]

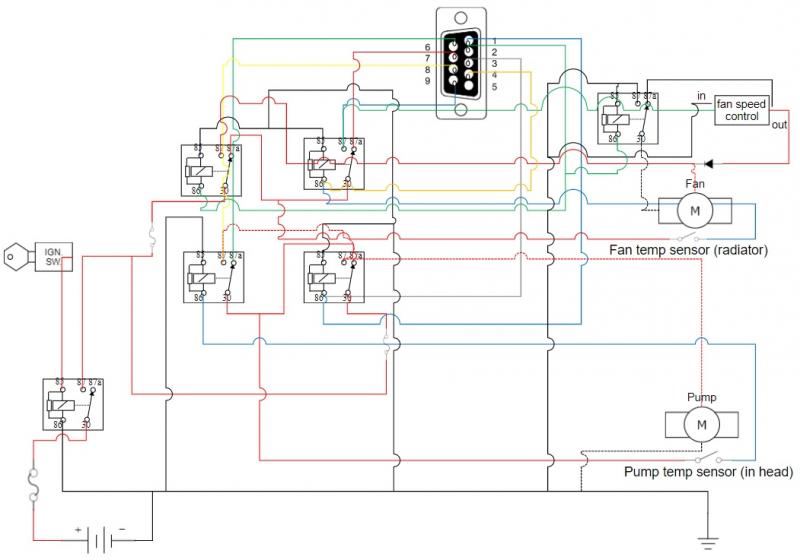

Finally, if anybody here is feeling wild and crazy, and wants to replicate my automation shenanigans, here's a

wiring diagram for my black box of spooky voodoo automagic. One thing to keep in mind is the DB9 connector at the top is only there to drive the override switches (pump/fan) and keep an eye on the state of the relays. You could run this box without the override switches or monitoring LED's, just eliminate the DB9 connector and it's leads. I'd advise against it personally though, if you do attempt this design. I believe the more information the better, work smarter not harder! Let me know if you have any questions!

Attachment:

oh_my_god_so_many_wires.jpg [ 47.88 KiB | Viewed 19031 times ]

oh_my_god_so_many_wires.jpg [ 47.88 KiB | Viewed 19031 times ]