I started this build in 2017. What an awesome resource of information this forum is! The goal of this project is a cheap, fast, fun buggy for primarily riding sand on the Oregon coast. Time and money resources have fluctuated greatly since starting this project, so hopefully posting here will help me finish it. I grew up riding Banshees on the sand and that helped greatly sourcing parts and measurements.

Craigslist find. Few hundred bucks for a worn out 350 minus the Engine.

1.5" .125 tube and some used front banshee suspension with raptor 660 shocks and I ended up with this. 22 inch tires in the front, 24 inch tires in the rear. Hopefully help for lack of suspension but I have a few ideas for upgrades in that department too. Wheelbase is a few inches longer and the front is as equally as wide as the rear.

Craigslist strikes again! Donor vehicle. 1996 yamaha exciter II 570. It was the "wifes sled". Took it for a rip in the mountains and it ran awesome. Water cooled, electric start, twin carb and simple dash. So I tore it apart!

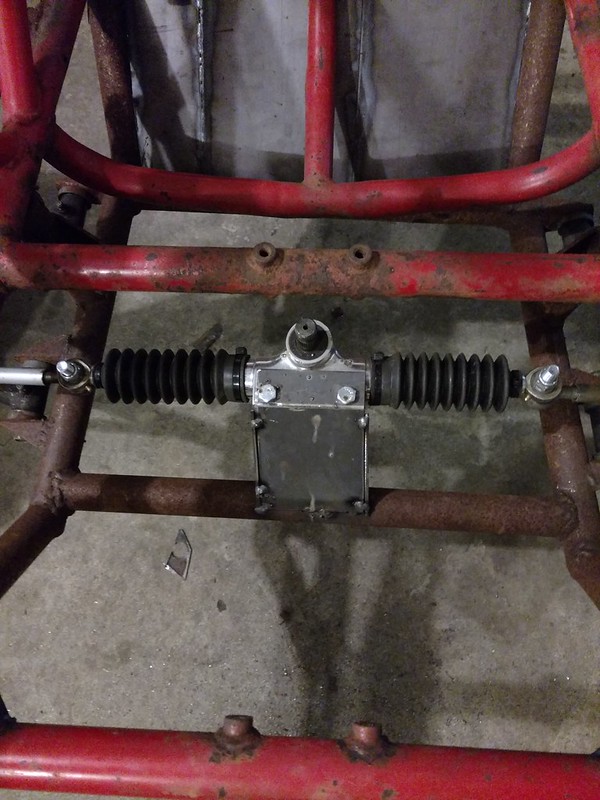

Fast forward a few months. I came to realize how much bigger the 570 is than the 350 and why people have stretched the frame on these. In my opinion that looks unproportional to me. So I made it fit. I will rebuild the frame comparable to what I cut out. To combat bump steer I made a cantilever type steering setup that ended up having no leverage so it all got cut off. What also puzzled me is, how in the world am I going to keep the front end from never touching the ground?!

Alright months later I picked up a 4.5 gallon tank, and rebuilt the stock ody seat with some much needed extra padding. I wanted to upgrade to something nicer but would have no room for the exhaust if I did that. Cheap steering rack on amazon and some .125 plate and bump steer is almost all eliminated. After fighting with the clutch alignment .125 plate makes the front

motor ((

Internal Combustion Engine ? )) mounts.

So next came the issue of clutches. First I had to fight with getting the factory secondary off the trans and ended up cutting it off. After some measuring I had a local machine shop rob my bank account for a piece of hardened steel. Output of 350 trans shaft on one end and factory yamaha secondary drive shaft on the other with plenty of surface to mount a support roller bearing I took from the sled. Fits perfect. This was sometime last spring.

Last year I buckled down and worked a lot, and it wasn't on this. Traveling the country for work hurts the timing on a project like this. So I fixed that.

The garage may be small but its still a garage. My neighbors love me heh.

I've made some good progress since that last picture and will share that soon. Brakes, steering, wiring, exhaust, Engine mounts, output shaft support bearing, rear suspension, and a steel foot tub are mostly figured out. That will put us up to date with the project.

I need some rear suspension joints that are in decent shape or preferable brand new. Or should I grab some from Ruff Stuff and build my own? Try my best to find information that has already been asked/answered before asking here but I may run into a few things and that's why I brought this thread over from other forums.

Thanks for lookin.